How Flexible Busbar Bending Tools are Shaping the Future of Electrical Installations

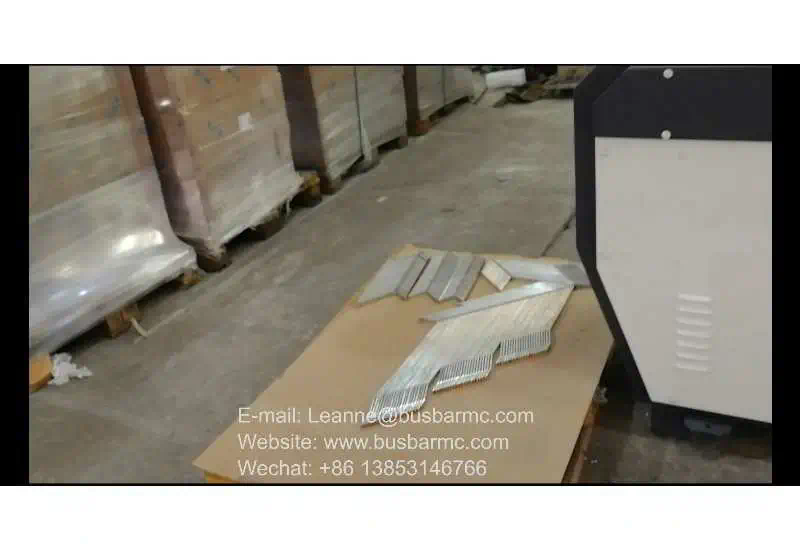

Electrical installations play a crucial role in powering our modern world, whether it’s in residential, commercial, or industrial settings. One key component of these installations is the busbar, which serves as a conductor of electricity within switchgear, distribution boards, and other electrical equipment. Traditionally, bending and shaping busbars required specialized tools and skills, but thanks to advances in technology, flexible busbar bending tools are now revolutionizing the way electrical installations are carried out.

Flexible busbar bending tools are designed to streamline the process of bending and shaping busbars, offering greater flexibility, accuracy, and efficiency compared to traditional methods. These tools come in various shapes and sizes, allowing electricians and technicians to create complex bends and shapes with ease. In this article, we will explore how flexible busbar bending tools are sheet metal forming machines shaping the future of electrical installations.

Enhanced Precision and Accuracy

One of the key advantages of flexible busbar bending tools is their ability to provide enhanced precision and accuracy in shaping busbars. Traditional methods of bending busbars often rely on manual measurements and bending techniques, which can lead to inconsistencies and errors. With flexible busbar bending tools, electricians can input precise measurements and angles, ensuring that each bend is executed with the utmost accuracy.

These tools utilize advanced technology, such as digital displays and programmable settings, to help users achieve the desired bend angles and shapes with minimal room for error. The result is a more precise and accurate final product, which is essential for ensuring the reliability and safety of electrical installations.

Increased Efficiency and Productivity

Flexible busbar bending tools are also significantly more efficient than traditional bending methods, helping to streamline the installation process and improve overall productivity. These tools allow electricians to bend busbars quickly and easily, reducing the time and effort required to complete complex bending tasks.

Furthermore, the versatility of flexible busbar bending tools means that electricians can work more efficiently without the need for multiple tools or setups. This not only saves time but also reduces the risk of errors and rework, ultimately leading to a more efficient and productive workflow.

Versatility and Adaptability

Another key benefit of flexible busbar bending tools is their versatility and adaptability to a wide range of busbar sizes and shapes. These tools are designed to accommodate various busbar materials, including copper and aluminum, as well as different thicknesses and widths.

Moreover, flexible busbar bending tools can create bends in multiple planes, allowing for the creation of complex shapes and configurations that would be challenging or impossible to achieve using traditional methods. This level of versatility enables electricians to tackle a wider range of projects and applications, making these tools indispensable in today’s diverse electrical industry.

Improved Safety and Ergonomics

Safety is always a top priority in electrical installations, and flexible busbar bending tools are designed with safety in mind. These tools feature built-in safety mechanisms, such as automatic shut-off functions and overload protection, to prevent accidents and injuries during operation.

Furthermore, the ergonomic design of flexible busbar bending tools helps reduce strain and fatigue on the user, ensuring a comfortable and efficient working experience. By minimizing physical exertion and repetitive motions, these tools not only enhance safety but also contribute to the overall well-being of electrical technicians.

Cost-Effectiveness and Long-Term Savings

While flexible busbar bending tools may represent an initial investment, their cost-effectiveness becomes apparent in the long run. By streamlining the bending process and improving efficiency, these tools help reduce labor costs and increase productivity, resulting in long-term savings for electrical contractors and businesses.

Additionally, the precise and accurate bends created by flexible busbar bending tools can contribute to the longevity and reliability of electrical installations, reducing the likelihood of costly repairs and maintenance down the line. This combination of efficiency, accuracy, and durability makes flexible busbar bending tools a wise investment for any electrical installation project.

The Future of Electrical Installations

Flexible busbar bending tools represent a significant advancement in the field of electrical installations, offering a combination of precision, efficiency, versatility, and safety that traditional bending methods cannot match. As technology continues to evolve, we can expect further innovations in busbar bending tools, leading to even greater advancements in the way electrical installations are designed and executed.

By embracing flexible busbar bending tools, electricians and technicians can enhance the quality, reliability, and safety of electrical installations, ultimately shaping a future where efficiency and innovation go hand in hand. With their ability to simplify complex bending tasks and improve overall workflow, these tools are set to play a pivotal role in shaping the future of electrical installations for years to come.

In conclusion, flexible busbar bending tools are reshaping the landscape of electrical installations, offering a glimpse into the possibilities of a more efficient, precise, and safe approach to busbar bending. As the demand for high-quality electrical installations continues to grow, these tools will undoubtedly play a crucial role in meeting the industry’s evolving needs and standards.

How Flexible Busbar Bending Tools are Shaping the Future of Electrical Installations

Electrical installations play a crucial role in powering our modern world, whether it’s in residential, commercial, or industrial settings. One key component of these installations is the busbar, which serves as a conductor of electricity within switchgear, distribution boards, and other electrical equipment. Traditionally, bending and shaping busbars required specialized tools and skills, but thanks to advances in technology, flexible busbar bending tools are now revolutionizing the way electrical installations are carried out.

Flexible busbar bending tools are designed to streamline the process of bending and shaping busbars, offering greater flexibility, accuracy, and efficiency compared to traditional methods. These tools come in various shapes and sizes, allowing electricians and technicians to create complex bends and shapes with ease. In this article, we will explore how flexible busbar bending tools are shaping the future of electrical installations.

Enhanced Precision and Accuracy

One of the key advantages of flexible busbar bending tools is their ability to provide enhanced precision and accuracy in shaping busbars. Traditional methods of bending busbars often rely on manual measurements and bending techniques, which can lead to inconsistencies and errors. With flexible busbar bending tools, electricians can input precise measurements and angles, ensuring that each bend is executed with the utmost accuracy.

These tools utilize advanced technology, such as digital displays and programmable settings, to help users achieve the desired bend angles and shapes with minimal room for error. The result is a more precise and accurate final product, which is essential for ensuring the reliability and safety of electrical installations.

Increased Efficiency and Productivity

Flexible busbar bending tools are also significantly more efficient than traditional bending methods, helping to streamline the installation process and improve overall productivity. These tools allow electricians to bend busbars quickly and easily, reducing the time and effort required to complete complex bending tasks.

Furthermore, the versatility of flexible busbar bending tools means that electricians can work more efficiently without the need for multiple tools or setups. This not only saves time but also reduces the risk of errors and rework, ultimately leading to a more efficient and productive workflow.

Versatility and Adaptability

Another key benefit of flexible busbar bending tools is their versatility and adaptability to a wide range of busbar sizes and shapes. These tools are designed to accommodate various busbar materials, including copper and aluminum, as well as different thicknesses and widths.

Moreover, flexible busbar bending tools can create bends in multiple planes, allowing for the creation of complex shapes and configurations that would be challenging or impossible to achieve using traditional methods. This level of versatility enables electricians to tackle a wider range of projects and applications, making these tools indispensable in today’s diverse electrical industry.

Improved Safety and Ergonomics

Safety is always a top priority in electrical installations, and flexible busbar bending tools are designed with safety in mind. These tools feature built-in safety mechanisms, such as automatic shut-off functions and overload protection, to prevent accidents and injuries during operation.

Furthermore, the ergonomic design of flexible busbar bending tools helps reduce strain and fatigue on the user, ensuring a comfortable and efficient working experience. By minimizing physical exertion and repetitive motions, these tools not only enhance safety but also contribute to the overall well-being of electrical technicians.

Cost-Effectiveness and Long-Term Savings

While flexible busbar bending tools may represent an initial investment, their cost-effectiveness becomes apparent in the long run. By streamlining the bending process and improving efficiency, these tools help reduce labor costs and increase productivity, resulting in long-term savings for electrical contractors and businesses.

Additionally, the precise and accurate bends created by flexible busbar bending tools can contribute to the longevity and reliability of electrical installations, reducing the likelihood of costly repairs and maintenance down the line. This combination of efficiency, accuracy, and durability makes flexible busbar bending tools a wise investment for any electrical installation project.

The Future of Electrical Installations

Flexible busbar bending tools represent a significant advancement in the field of electrical installations, offering a combination of precision, efficiency, versatility, and safety that traditional bending methods cannot match. As technology continues to evolve, we can expect further innovations in busbar bending tools, leading to even greater advancements in the way electrical installations are designed and executed.

By embracing flexible busbar bending tools, electricians and technicians can enhance the quality, reliability, and safety of electrical installations, ultimately shaping a future where efficiency and innovation go hand in hand. With their ability to simplify complex bending tasks and improve overall workflow, these tools are set to play a pivotal role in shaping the future of electrical installations for years to come.

In conclusion, flexible busbar bending tools are reshaping the landscape of electrical installations, offering a glimpse into the possibilities of a more efficient, precise, and safe approach to busbar bending. As the demand for high-quality electrical installations continues to grow, these tools will undoubtedly play a crucial role in meeting the industry’s evolving needs and standards.

https://devicesplayer.com/