If a part is to be printed in a multi-material, then the part is designed in CAD as an assembly. Each section of the part that is to be printed in a different material is created as its own part file, then integrated into the final assembly to make the multi-material part. Note: mated parts in the assembly should be flush to surfaces, any gaps will fill with support material and cause cosmetic or mechanical errors.

When the part is completed and ready for submission, Xometry recommends exporting the assembly as a .step file when uploading it to the instant quoting site. This allows all the parts to be contained and managed easily in a single file.

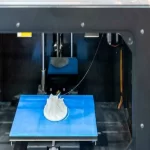

During production, parts are built just as a normal, single material PJ3D part, but with the print head depositing multiple materials at the same time instead of just one.

.webp)