Designing high-performance graphite condensers presents a range of challenges that engineers and designers must navigate to achieve optimal efficiency and reliability. This article explores these challenges in detail while also proposing effective solutions, ensuring a comprehensive understanding of the subject.

p The demand for efficient heat exchange systems has led to the increasing use of graphite condensers in various industries, including power generation, chemical processing, and HVAC systems. Graphite’s unique properties, such as its excellent thermal conductivity, resistance to corrosion, and ability to withstand high temperatures, make it an ideal material for condenser design. However, the complexity of operating conditions and specific application requirements can create significant obstacles.

h2 Challenges in Designing Graphite Condensers

h3 Material Limitations and Selection

p One of the foremost challenges in designing graphite condensers is the selection of appropriate materials. While graphite boasts numerous advantages, such as high thermal conductivity and chemical resistance, its mechanical properties can vary significantly depending on the type and manufacturing process. Designers must choose between different types of graphite, such as isotropic or anisotropic, and consider factors like density, porosity, and strength.

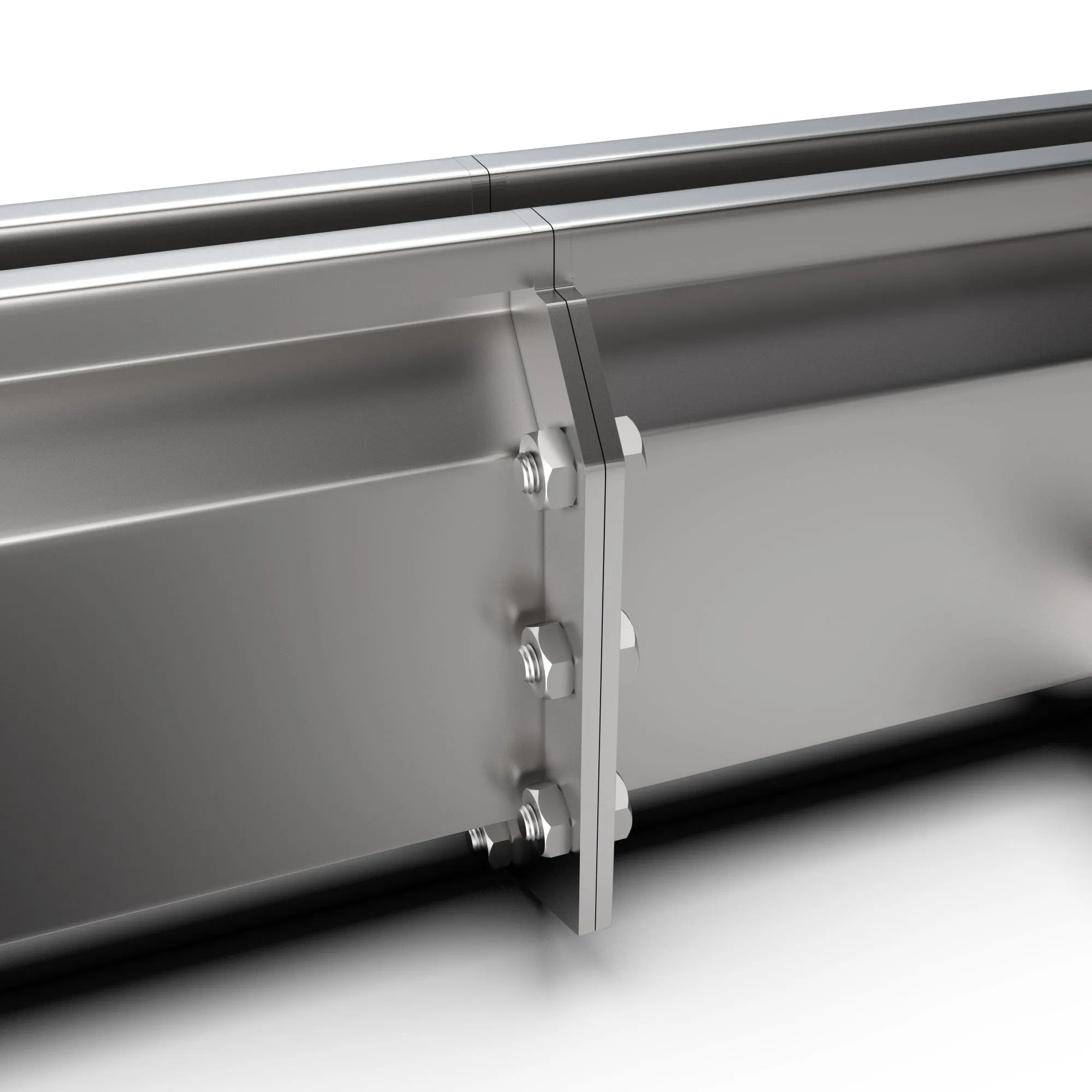

p In applications where mechanical stress is prevalent, the brittleness of graphite can pose a risk. Designers need to ensure that the selected material can withstand operational pressures without fracturing. Compounding this issue, the thermal expansion characteristics of graphite differ from those of metals, necessitating careful consideration of joint designs and support structures to avoid failure.

h3 Thermal Performance Optimization

p Achieving optimal thermal performance is another significant challenge. The design of a graphite condenser must facilitate efficient heat transfer while minimizing pressure drops across the system. Factors such as flow rate, temperature gradients, and surface area play critical roles in this aspect.

p Designers often employ complex computational fluid dynamics (CFD) simulations to model heat transfer and fluid flow within the condenser. These simulations help identify inefficiencies in design and allow for the optimization of geometries. However, accurately predicting the behavior of fluids and thermal gradients in real-world conditions can be complicated due to variations in operating environments.

h3 Corrosion and Fouling

p Although graphite is highly resistant to many corrosive substances, certain chemicals can still lead to degradation over time. In particular, the presence of acidic or alkaline solutions can compromise the integrity of graphite condensers. Furthermore, fouling—caused by the accumulation of unwanted materials on heat exchange surfaces—can significantly reduce heat transfer efficiency.

p To mitigate these issues, it is crucial to conduct thorough material compatibility assessments during the design phase. Implementing regular maintenance schedules and using coatings or treatments to enhance corrosion resistance can also extend the life of the condenser and ensure reliable performance.

h2 Solutions to Overcome Design Challenges

h3 Advanced Material Selection

p To address the limitations of traditional graphite materials, researchers are exploring advanced composites and hybrid materials. By combining graphite with polymers or metals, designers can enhance mechanical properties while retaining the thermal benefits of graphite. These innovative materials can provide improved toughness and flexibility, making them suitable for more demanding applications.

p Additionally, the development of engineered graphite products, such as reinforced or laminated graphite, offers promising solutions. These materials can be tailored to meet specific performance criteria, ensuring that the final product can withstand both thermal and mechanical stresses.

h3 Innovative Design Techniques

p Employing advanced design techniques can dramatically improve the thermal performance of graphite condensers. For instance, utilizing finned or corrugated designs increases the surface area available for heat exchange, enhancing overall efficiency. Incorporating features such as variable geometry can also help adapt the condenser to changing operational conditions, optimizing performance across a range of scenarios.

p Moreover, leveraging additive manufacturing technologies can enable the creation of complex geometries that traditional manufacturing methods cannot achieve. This approach allows for the customization of flow paths and surface textures, further improving heat transfer and reducing pressure losses.

h3 Enhanced Maintenance Strategies

p Implementing proactive maintenance strategies is critical to overcoming the effects of corrosion and fouling. Regular inspection and cleaning schedules can help identify potential issues before they escalate into significant problems. Utilizing non-destructive testing methods can assess the integrity of the condenser without causing damage, allowing for timely interventions.

p Additionally, the incorporation of self-cleaning coatings or materials can help minimize fouling. These innovative solutions can reduce the frequency of manual cleaning, thereby lowering maintenance costs and improving operational efficiency.

h2 Case Studies

h3 Application in Power Generation

p A notable example of successful graphite condenser design is found in the power generation sector. Here, high-performance graphite condensers have been implemented to replace traditional metal condensers, resulting in improved thermal efficiency and reduced operational costs. By carefully selecting materials and employing advanced design techniques, these condensers have demonstrated extended service life and reduced maintenance needs.

p The use of CFD modeling in this application allowed engineers to optimize flow distribution and minimize pressure losses, leading to a marked increase in overall system efficiency. As a result, power plants utilizing these advanced graphite condensers have seen significant improvements in energy output and sustainability.

h3 Chemical Processing Industry

p In the chemical processing industry, graphite condensers have become indispensable for processes that involve highly corrosive substances. One particular case involved the redesign of a condenser used in the production of specialty chemicals. By integrating advanced composite materials and innovative engineering designs, the new condenser not only enhanced durability but also improved heat transfer rates.

p The implementation of a rigorous maintenance program ensured the longevity of the condenser, ultimately leading to lower operational costs and increased reliability. This case illustrates the importance of addressing material selection and maintenance strategies in achieving high-performance outcomes.

h2 Future Directions

h3 Emerging Technologies and Trends

p As industries continue to evolve, graphite steam ejector condenser the demand for more efficient and durable graphite condensers will only grow. Emerging technologies such as nanomaterials and smart coatings hold promise for further enhancing the performance and resilience of these systems. Research into graphene-based materials, for instance, could revolutionize the thermal management capabilities of condensers, offering unprecedented levels of efficiency.

p Furthermore, the integration of digital monitoring systems can provide real-time data on condenser performance, enabling predictive maintenance and immediate responses to potential failures. This level of oversight can significantly enhance the reliability and efficiency of graphite condensers in various applications.

h3 Sustainable Practices

p Sustainability is becoming increasingly important in engineering design. As such, future graphite condenser designs will likely focus on not only performance but also environmental impact. The use of recyclable materials and energy-efficient manufacturing processes will be essential in creating sustainable solutions.

p Additionally, the development of condensers that utilize waste heat recovery systems can contribute to overall energy efficiency. By leveraging the heat produced in industrial processes, these systems can enhance the overall sustainability of operations, aligning with global efforts to reduce carbon footprints.

p In conclusion, designing high-performance graphite condensers involves navigating a unique set of challenges, from material selection to maintenance strategies. However, by employing innovative design techniques and advanced materials, engineers can overcome these obstacles to create efficient, reliable, and sustainable systems. As technology continues to advance, the future of graphite condensers looks promising, with opportunities for enhanced performance and reduced environmental impact.

https://devicesplayer.com/