MoDTP – A Comprehensive Review of Its Use in Lubricants

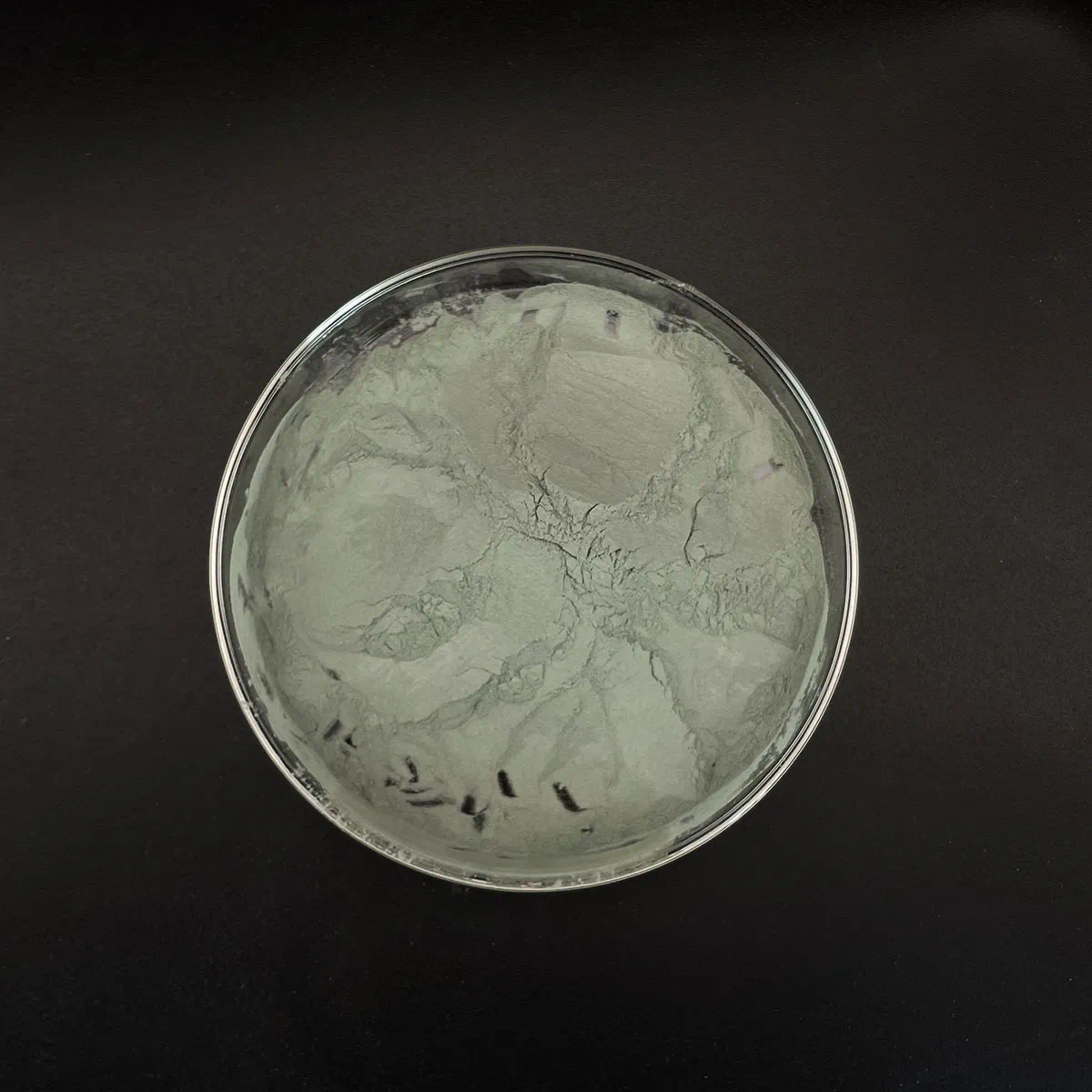

p MoDTP, or molybdenum dialkyldithiophosphate, has gained significant attention in the field of lubrication due to its unique properties and capabilities. This compound is recognized for its multifunctional characteristics, making it a vital additive in various lubricant formulations. In this review, we will explore the chemistry, benefits, applications, and future perspectives of MoDTP in lubricants.

h2 Understanding MoDTP Chemistry

p The molecular structure of MoDTP consists of a molybdenum atom coordinated with dialkyldithiophosphate groups. The presence of sulfur and phosphorus in its structure enhances its effectiveness as an anti-wear and anti-corrosion agent. The typical synthesis involves the reaction of molybdenum trioxide with dialkyldithiophosphoric acid, resulting in a compound that exhibits excellent thermal stability and low volatility.

p This chemistry allows MoDTP to function effectively under extreme pressure and temperature conditions. As a result, it provides significant protection to metal surfaces, reducing friction and wear during operation. Its ability to form a protective film on metal surfaces contributes to its popularity in high-performance lubricants.

h2 Benefits of MoDTP in Lubricants

p One of the primary benefits of MoDTP is its outstanding anti-wear properties. In applications where metal-to-metal contact is inevitable, the presence of MoDTP can significantly reduce wear rates. Studies have shown that lubricants containing MoDTP outperform traditional additives in protecting engine components from wear.

p Additionally, MoDTP serves as an antioxidant, extending the life of lubricants by preventing oxidative degradation. This property is particularly crucial in environments where lubricants are exposed to high temperatures and reactive species. By inhibiting oxidation, MoDTP helps maintain the integrity of the lubricant, ensuring consistent performance over time.

h3 Corrosion Resistance

p Another significant advantage of MoDTP is its ability to provide corrosion resistance. The formation of a protective layer on metal surfaces not only minimizes wear but also protects against corrosive agents such as moisture and acids. This feature is especially important in marine and industrial applications where equipment is often exposed to harsh conditions.

h2 Applications of MoDTP in Various Industries

p MoDTP is widely used across various industries, including automotive, aerospace, and manufacturing. In the automotive sector, it is commonly found in engine oils, transmission fluids, and gear oils. The incorporation of MoDTP enhances the performance of these lubricants, providing better protection and efficiency.

p In aerospace applications, where reliability is crucial, MoDTP is employed in high-performance lubricants for engines and hydraulic systems. The ability to function effectively under extreme conditions makes MoDTP an ideal choice for these demanding environments.

h3 Industrial Lubrication

p In manufacturing, MoDTP is utilized in cutting oils and hydraulic fluids, where the need for reliable lubrication is paramount. The anti-wear properties of MoDTP ensure that machinery operates smoothly, reducing downtime and maintenance costs.

h2 Future Perspectives of MoDTP in Lubricants

p As research continues, the potential uses of MoDTP in lubricants are expanding. With the increasing focus on sustainability and environmental impact, there is a growing interest in developing bio-based Hpmc Hydroxypropyl Methylcellulose lubricants. MoDTP’s compatibility with renewable resources positions it as a promising additive in the formulation of environmentally friendly lubricants.

p Moreover, advancements in nanotechnology may lead to the development of new formulations where MoDTP can be combined with nanoparticles for enhanced performance. These hybrid lubricants could offer superior properties compared to conventional options, paving the way for more efficient and sustainable lubrication solutions.

h3 Regulatory Considerations

p Despite its many benefits, the use of MoDTP in lubricants is not without challenges. Regulatory concerns regarding the environmental impact of certain additives have led to increased scrutiny. Manufacturers must navigate these regulations carefully, ensuring that their products meet safety and performance standards while also addressing sustainability concerns.

h2 Conclusion

p In conclusion, MoDTP represents a versatile and effective additive in the world of lubricants. Its unique chemical properties contribute to improved performance in various applications, providing anti-wear, antioxidant, and corrosion-resistant benefits. As industries evolve and the demand for efficient and sustainable solutions grows, MoDTP will likely continue to play a crucial role in the formulation of advanced lubricants. Researchers and manufacturers must collaborate to harness its full potential while addressing environmental and regulatory challenges. The future of MoDTP in lubrication looks promising, with opportunities for innovation and growth in the coming years.

https://devicesplayer.com/